Since inception, the principal owner of Mashovhela Lodge, Dr. H.H. Hahn, made a conscious decision not to connect to the public power grid, but instead to use renewable energy, wherever possible, to satisfy the energy needs of the Lodge and make it a research and testing ground, prototype and showpiece for renewable energy. In recognition of Dr Hahn’s achievements Mashovhela Lodge has been awarded the Gold Leaf by the Wilderness Foundations Green Leaf Standard which measures efficiencies in the environmental life cycle, for example water, energy, waste, green procurement, innovation and social economic development.

Two innovative energy management systems are in place, namely Power and Heating, both designed by Dr Hahn, which over the last 2 years have been refined and improved and will continue to evolve as the years go by.

A new tented camp is under construction as part of the Lodge and our 1 prototype tent uses LPG for hot water. On completion of the camp, its hot water system will be upgraded to an energy consumption management system improved upon, but smaller than that of the main Lodge.

Heating

The following diagram reflects the status in July 2009. Since then the system has been upgraded further as set out below.

Solar hot water

Two different systems are in use at the Lodge, namely: flat solar hot water panels modified by Dr Hahn from a design published about 40 years ago by the South African Council for Scientific and Industrial Research (CSIR) and a more sophisticated and efficient system, developed and internationally patented by Dr H H Hahn, based on a more recent invention by Helmut Nass.

The experience at the Lodge has since enabled Dr H H Hahn and his team to design an entirely new SWH flat panel about to be installed for the tented camp and all future extensions. Tooling-up for mass production of the panel in South Africa for worldwide sales is already taking place. This improved flat panel is assembled from black anodised extruded aluminium profiles, specially designed for extreme thermal efficiency, lightness and low cost.

Wood-burning hot water boilers

Unfortunately the sun does not shine 24 hours a day and we can only bank on an average of 6 hours a day so the solar systems are supplemented by wood-burning hot water boilers.

At Mashovhela Lodge these are custom-built, highly efficient, wood-burning small hot water boilers designed by Dr H.H. Hahn. In the first test run, such a boiler brought a 700 litre hot water tank to the boil in just over half an hour, thus ensuring that hot water will always be available even when the weather is bad.

Total capacity of renewable hot water system

Since the status reflected in Annexure 1, the capacity has been increased (and is in the process of being further increased). During the year under review: –

Hot water tank capacity from 2000 l to 3000 l.

Flat panel area from 18 to 26 m2.

This alone is equivalent to 26 kW of conventional geyser capacity. Assuming 6 hrs of sunshine per day for 250 days per year, this is equivalent to 39’000 kWh/a. This could be doubled by the output of the wood-fired boilers to 50 kW, if needed, but at present still only partly used, using about 2000 kg firewood/a equivalent to 3000 kWh/annum.

The tented camp under construction will add to the above 1000 l hot water tank capacity and about 8 kW panel capacity plus boiler capacity as needed.

All firewood requirements of the Lodge are met by utilising wood recovered from the Nature Reserve’s exotics (eucalyptus and wattle) and bush encroachment control programs.

Space heating main building

Restaurant | Reception | Bar | Conference Rooms

A large centrally-placed, freestanding, wood-fired fire place (own design, custom-built) is usually the only source of heat for space heating, using up to about 30 kg firewood per day in winter (only when there are guests) and about 15 kg/night on chilly evenings in summer. Average firewood (wattle and blue gum only) consumption about 5000 kg/annum (equivalent to 7500 kWh/a). Occasionally, an LPG-fuelled gas heater is used, mainly in conference room.

The above replaces (assuming power grid connection) a minimum of 5 electric heaters of 2000 W each, used a minimum of 600 hrs per year equivalent to a demand capacity of 10 kW and a consumption of 12000 kWh/a.

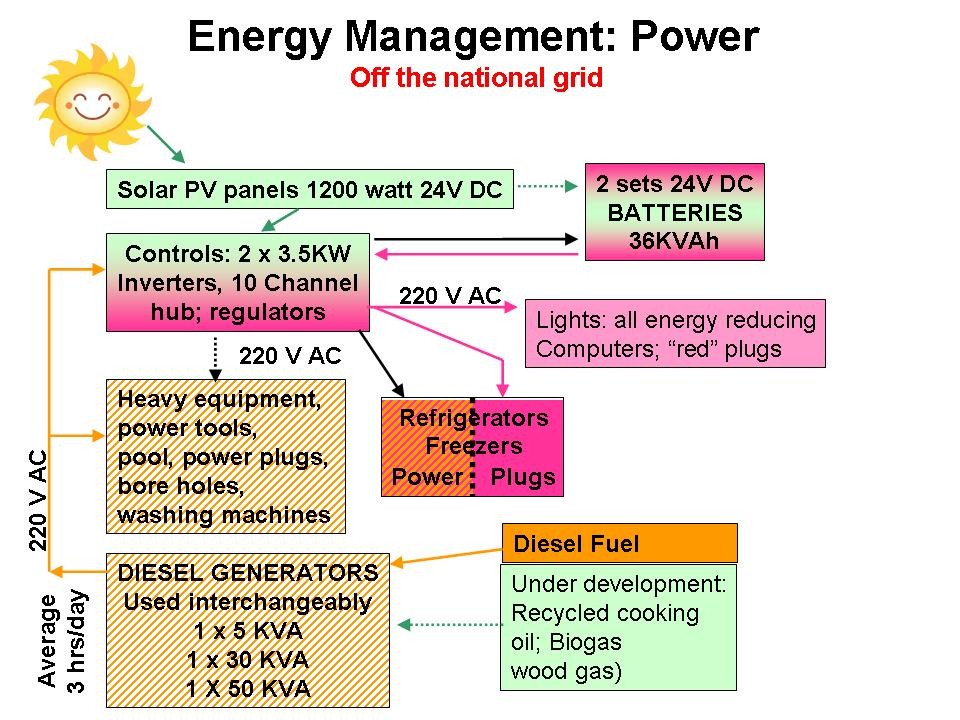

Power

The following diagram illustrates the concept of being ‘off the National grid’.

Solar electricity (PV-panels)

The Lodge in July 2009 had a 1200 Watt array of PV panels mounted at an angle to the sun which is optionally adjustable, depending on the season, for maximum output.

A second inverter and a 10 channel hub have since been installed; this improves the simultaneous capturing of solar energy and the charging batteries from surplus generator power while generator is on.

The existing system used to charge a 24 V set of batteries (capacity 36 kVA). This has been upgraded with new batteries with a 33.3% higher capacity of 48 kVA, enough to supply all the lighting and an increase in power requirements of the Lodge. The DC voltage is inverted to 220 V AC (50 Hertz). Testing of the new batteries is presently in progress to see to what extent we can reduce the diesel consumption of our generators (see below). In addition, a further 200 Watt PV panels, plus a matching further inverter and matching additional batteries were purchased, waiting to be installed.

Guests and staff are encouraged to use electricity sparingly.

Generator power

The generator house has now three diesel generators of 5 kVA, 30 kVA and 50 kVA respectively, any one of which can be used at a given time to supplement the output of PV-panels above as needed.

Peak consumption has already been reduced from 50 kVA to 30 kVA by replacement of the previous 15 kVA generator by the 30 kVA generator. The 50 kVA generator is now only used as stand-by, resulting in the saving of diesel consumption of about 15%.

Further generator power has been reduced to 3 – 4 hours per day, unless construction machinery is used or the Lodge occupancy is high.

The aforegoing, not counting what is planned for the tented camp, would be equivalent (if connected to the grid) to an additional 30 – 50 kW demand capacity and consumption from the Eskom grid of about 100 000 kWh/a.

Since the opening of the Lodge 3 years ago, incandescent lamps have been strictly banned on the Lodge and have been replaced throughout by Compact Fluorescent Lights (CFL), LEDs and energy-saving light tubes. This has resulted in 80% power savings on outdoor and indoor lighting alone.

Summary of energy demand, consumption savings and reduced carbon footprint (excluding expansions under construction).

Calculation of energy demand and consumption savings

Total demand savings to the national grid:

| Hot water | 50 kW |

| Space heating | 10 kW |

| Cooking etc | 40 kW |

| lighting, pumping, mechanical power | 50 kW |

| at least | 150 kW |

(capital saving to Eskom, disregarding distribution network, 4,5 million Rand)

Total savings in consumption from the grid:

| Hot water | 40 000 kWh/a |

| Space heating and kitchen | 26 000 kWh/a |

| Other power | 100 000 kWh/a |

| at least | 166 000 kWh/a |

(since savings due to energy-saving lighting have not been calculated).

Calculation of reduced carbon footprint

The “renewable” portion of the above consumption figure is about 56 000 kWh/a. This is approximately equivalent to an annual reduction of CO2 emissions of 55 tons per annum.

The purported figure for CO2 emissions by Eskom’s power stations is 950 g CO2/kWh. (This is actually an understatement, because many factors are not accounted for).

As soon as the present diesel consumption of the generators can be replaced by biofuels and the LPG can be replaced by biogas or wood gas (see below), this would render the entire Lodge consumption “carbon neutral” (zero net emission of CO2). This would increase the reduction of CO2 emissions to 158 (using the above understated factor).

Space heating main building

Restaurant | Reception | Bar | Conference Rooms

A large centrally-placed, freestanding, wood-fired fire place (own design, custom-built) is usually the only source of heat for space heating, using up to about 30 kg firewood per day in winter (only when there are guests) and about 15 kg/night on chilly evenings in summer. Average firewood (wattle and blue gum only) consumption about 5000 kg/annum (equivalent to 7500 kWh/a). Occasionally, an LPG-fuelled gas heater is used, mainly in conference room.

The above replaces (assuming power grid connection) a minimum of 5 electric heaters of 2000 W each, used a minimum of 600 hrs per year equivalent to a demand capacity of 10 kW and a consumption of 12000 kWh/a.

CURRENT RESEARCH

Thermochemical gasification of biomass (“wood gas”)

Dr Hans H. Hahn, principal owner of the Lodge, has been engaged for 40 years, first in collaboration with Forschungszentrum Jülich (formerly “KfA”) in Germany, and later in collaboration with Prof. H. Mosch of FH Giessen, Germany, to develop sophisticated, patented technology for non-polluting thermochemical gasification of carbonaceous solids, in particular biomass and organic waste materials to produce an environmentally-friendly, engine-compatible fuel gas. Prototypes are being designed for local production and, when ready, such a plant will produce gas for running the power generators of the Lodge as well as for cooking in place of LPG.

Other biofuels compatible with the generators and vehicles used by the Lodge are also at present under study.

Micro-pump storage

Mashovhela Lodge serves as a demonstration project for alternative energy. With this in mind, it is intended to install a small pump storage reservoir at an ecologically selected site in the mountain above the Lodge for storing excess power generated by the solar and other systems and recouping this energy when needed by means of a micro-turbine. The small storage reservoir in the mountain could also collect rainwater and, in addition, provide a source of high pressure water in case of fire.